Working hours : Mon - Sat : 10AM - 7PM

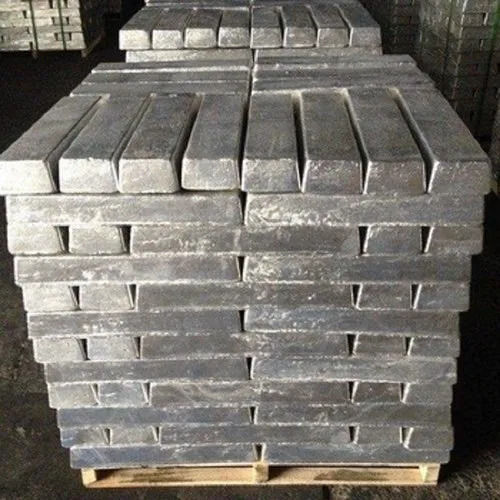

Magnesium Slab

260 INR/Kilograms

Product Details:

- Metal Type Non-Ferrous

- Purity(%) 99.80%

- Particle Size Customizable upon request

- Melting Point 650C

- Grade Industrial Grade

- Usage & Applications Aerospace, automotive, electronic industries, chemical processing

- Boiling point 1090C

- Click to View more

X

Magnesium Slab Price And Quantity

- 300 Kilograms

- 260 INR/Kilograms

Magnesium Slab Product Specifications

- Rectangular Slab

- Standard and custom sizes available

- 1090C

- Customizable upon request

- Pure Magnesium

- 650C

- Industrial Grade

- Typically 10 kg to 100 kg per slab Kilograms (kg)

- Aerospace, automotive, electronic industries, chemical processing

- 99.80%

- Mg 99.80%, trace impurities

- Non-Ferrous

- 500 mm x 300 mm x 50 mm (customizable) Millimeter (mm)

- Silvery White

- 1.74 Gram per cubic centimeter(g/cm3)

Magnesium Slab Trade Information

- 1000 Kilograms Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

Product Description

A magnesium slab is a sizeable, flat piece of metal primarily composed of the chemical element magnesium, denoted by the symbol Mg and atomic number 12 on the periodic table. With distinctive properties spanning chemical reactivity to physical attributes, magnesium occupies a pivotal role across industries and scientific domains.

Chemical Properties:

Magnesium, situated in Group 2 of the periodic table, belongs to the alkaline earth metal category. Hosting two valence electrons, it readily forms divalent cations, rendering it chemically active and conducive to bonding with other elements. This propensity for diverse chemical reactions positions magnesium as a crucial component in various chemical processes.

Physical Traits:

A standout feature of magnesium is its notably low density, approximately one-fourth that of steel. This property, coupled with inherent strength, designates magnesium as an optimal choice for applications necessitating lightweight yet durable materials. With a melting point of 650 degrees Celsius (1202 degrees Fahrenheit) and a boiling point of 1090 degrees Celsius (1994 degrees Fahrenheit), magnesium's physical attributes bolster its diverse applications.

Industrial Significance:

Magnesiums industrial applications are vast and diverse, owing to its unique properties. Foremost among these is the creation of lightweight alloys. Magnesium's unparalleled strength-to-weight ratio renders it indispensable in industries like aerospace, automotive, and sports equipment. By amalgamating magnesium with other metals such as aluminum, zinc, and manganese, engineers engineer potent, lightweight materials that enhance fuel efficiency and overall performance across various sectors.

In aerospace, magnesiums lightweight nature substantially reduces aircraft and spacecraft weight, translating to improved fuel efficiency, augmented payload capacity, and enhanced flight performance. Simultaneously, the automotive sector relies on magnesium alloys for manufacturing engine blocks, transmission cases, and structural components. The inclusion of magnesium facilitates weight reduction, thereby enhancing fuel economy and mitigating emissions.

Additionally, magnesium finds application in the electronics industry. It's employed in crafting casings for laptops, cellphones, cameras, and other portable devices. Magnesium's blend of lightweight construction and durability suits contemporary electronic device demands. Its commendable thermal conductivity also contributes to heat dissipation, critical for maintaining optimal operational temperatures in electronic components.

Chemical and Metallurgical Applications:

Magnesiums reactivity and affinity for oxygen have relevance in various chemical processes. Particularly, it plays a pivotal role in the steel industry. Magnesium's introduction to steel production eliminates sulfur and oxygen impurities during the refining process. Furthermore, it functions as a reducing agent in diverse reactions, aiding in the formation of specific chemical compounds.

Biological Significance:

Beyond industrial applications, magnesium holds a vital role in biological systems. It serves as an essential nutrient for human health, participating in numerous physiological processes. Magnesium acts as a cofactor for over 300 enzyme systems governing various biochemical reactions within the body. These encompass energy production, DNA synthesis, and muscle function. Maintaining adequate magnesium intake is imperative for robust bones, nerve function, and a steady heartbeat.

Health and Safety Considerations:

While magnesium is pivotal for human health, overexposure to its compounds can be hazardous. Inhaling magnesium dust or fumes, particularly from combustion, can irritate the respiratory system and lead to "metal fume fever." Additionally, specific forms of magnesium can induce skin irritation or allergies upon contact.

Environmental Impact:

Magnesium extraction from ores can have ecological ramifications, including habitat disruption and substantial energy consumption. Proper disposal of magnesium scrap and waste is crucial to prevent adverse effects on ecosystems.

In summary, a magnesium slab transcends its status as mere metal, encapsulating the extraordinary attributes of magnesium as a lightweight, robust, and reactive element. Its contributions span industries from aerospace and automotive to electronics and metallurgy, underscoring its versatility and indispensability. As we continue exploring innovative applications and prioritize sustainability, magnesium's role in shaping technology and enhancing human well-being remains resolute.

Superior Electrical and Thermal Conductivity

Magnesium slabs offer outstanding electrical and thermal conductivity, making them an excellent choice for demanding industrial applications. Their low density and high purity contribute to their effectiveness in settings where lightweight and reliable heat or electrical transfer are vital, such as aerospace and electronics manufacturing.

Flexible Customization and Packing Options

Each magnesium slab can be tailored in size and particle granularity to suit specific application needs. Packaged securely in wooden crates or steel-strapped bundles, these slabs arrive ready for use. Clients can request both standard and custom sizes to match their project requirements.

Optimal Storage and Handling Practices

To maintain the quality and integrity of the magnesium slabs, they should be stored in dry conditions, free from direct contact with water or acids. Protective coating is recommended in harsh environments to enhance corrosion resistance and prolong product lifespan, especially during transportation or extended storage.

FAQ's of Magnesium Slab:

Q: How should magnesium slabs be stored to prevent degradation?

A: Magnesium slabs should be kept dry and stored away from direct contact with water or acids. For harsh environments, applying a protective coating is advised to ensure optimal corrosion resistance and maintain their integrity.Q: What is the recommended process for packaging and shipping magnesium slabs?

A: Magnesium slabs are packed in sturdy wooden crates or steel-strapped bundles to minimize damage during transit. This packaging method safeguards the slabs and complies with the standard ASTM B557/B93 guidelines for industrial shipments.Q: Where are magnesium slabs commonly used?

A: These slabs are widely utilized in aerospace, automotive, electronics, and chemical processing industries due to their excellent thermal and electrical conductivity, moderate corrosion resistance, and lightweight properties.Q: When can I expect delivery for bulk orders of magnesium slabs?

A: The standard lead time for bulk orders is 2 to 4 weeks, allowing for customization and packaging arrangements according to client requirements.Q: What benefit do magnesium slabs provide over other non-ferrous materials?

A: Magnesium slabs offer superior conductivity, a lightweight yet robust structure, and customizable options, making them highly advantageous for applications demanding strength, efficiency, and precise material specifications.Q: How can the particle size and dimensions of magnesium slabs be customized?

A: Particle size and overall slab dimensions can be adjusted based on specific client needs. Customers can request custom sizes and grades to suit unique applications, facilitating maximum flexibility in industrial projects.Q: What is the minimum order quantity and standard purity for magnesium slabs?

A: The minimum order quantity is 500 kg per shipment. All slabs are guaranteed to have a magnesium purity of 99.80% or higher, ensuring performance meets industrial grade standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'metal product' category

"We are dealing only in Bulk Order Quantity"

Just submit your contact details and well be in touch shortly.

Back to top