Working hours : Mon - Sat : 10AM - 7PM

Showroom

We are dealing in the manufacturing and supplying of Magnesium Turnings Product that are produced during the machining of various types of products made up of aluminum. These scarp materials can be delivered to our customers in bulk as per their demands at a reasonable price range.

Magnesium Powder are fine free-flowing substances that are added as an alloying element in the production of various types of industrial materials. These powdered substances impart physical as well as chemical properties to the elements with which they are alloyed.

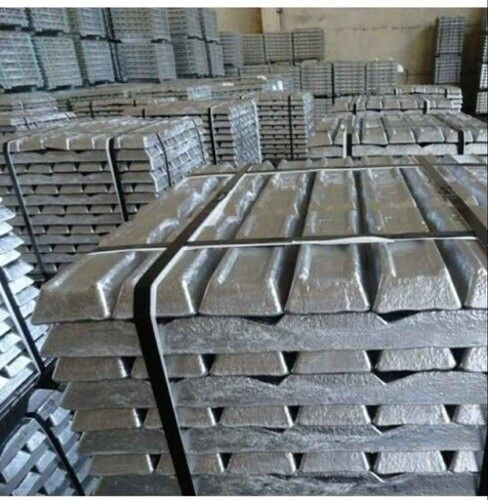

Empire Industries is a Gujarat, India-based manufacturer and supplier of top-grade Magnesium Metal Product that are available in solid forms in various shapes such as cuboidal and cubical billets. Buy from us these products in bulk at a reasonable price.

Metal Products availed by us encompass a diverse range of specialized items vital for industrial processes. Each product is engineered to withstand extreme temperatures and conditions, ensuring efficiency and durability in metallurgical operations.

"We are dealing only in Bulk Order Quantity"

Just submit your contact details and well be in touch shortly.

Back to top